Product Model: Various specificiations for choice

Production capacity: 0.62-180t/h

Material: Coal, cement, ore, calcite, cement clinker, dolomite, clay, coal, barite, and gypsum,etc.

Zhongde Heavy Industries Co., Ltd. China(Mainland)

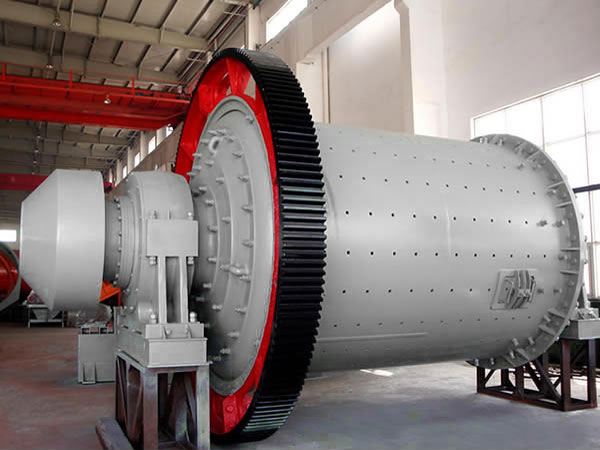

Being widely used in the level one grinding of the artificial sand preparation plant, chemical plant and the electric power department, rod mill is named according to the steel bar of the loading grinding barrel and there are dry type and wet type rod mills. Customers can choose them according to the practical situation.

1. The small curvature of the conical shell cover of the rod grinder make the steel bar rote regally in the mill. With larger diameter, the hollow shaft of the ore discharge not only make it easily examined but also lower the ore slurry surface in order to discharge fast. The product particle size is homogeneous.

2. With low medium filling rate of about 35%—40%, the rotary rate of the wet type rod mill is low and the common rate is between 60%—70%. The steel barrel will be distorted when rotating if the feed size is too large. At the same time, there will be larger space between the barrels and this will cause the decline of production. Minerals are crushed and grinded by the line contact of the falling of the barrel. The fine grains are rarely grinded.The length of the steel barrel is shorter than that of the cylindrical barrel by 25—50mm.

Rod grinder is the most important and widely used equipment in the raw material grinding operations. It is mainly selected in the coarse grinding operation and suitable for the fine grinding of the first open circuit grinding especially for processing brittle material.

Although it can be used for grinding all kinds of mineral and other materials by the ore dressing and building materials departments,the application range of the wet type rod mill is much more smaller than the ball mill and ball mill can replace wet type rod mill in many cases.

.jpg)

The wet type rod mill is mainly composed by the small diameter and long barrel which is driven via transmission machinery. The materials will be grinded in the barrel through the impact of the steel balls and the minerals and the finished products will be discharged from the end of the barrel. In the wet rod mill, in the wet grinding, the material is taken away by water flow, while in dry grinding, by air current.

| Model |

Shell Specifications (mm)

|

Shell rotation speed (r/min) |

Feeding size (mm) |

Discharging size (mm) |

Processing capacity (t/h) |

Power (kw) |

Total weight (t) |

|

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

NOTE: You can also send a message to us by this email vip@zdzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!