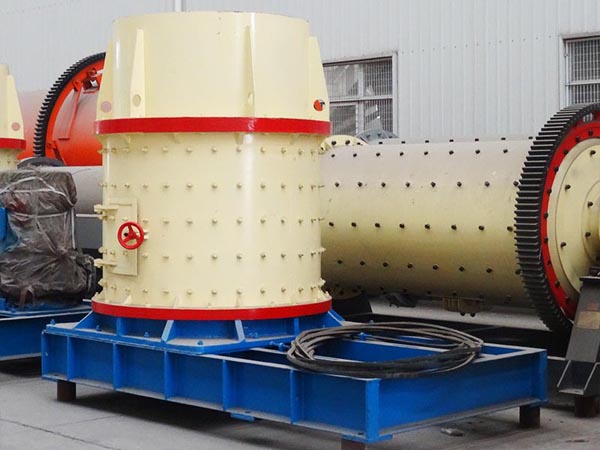

Processing capacity: 5-100t/h

Feeding size: 50-10mm

Output size: 0-5mm

Materials: dolomite, flint, lead and zinc, serpentine, blast furnace slag, coal gangue,phosphate rock, limestone, dolomite, granite, basalt

Zhongde Heavy Industries Co., Ltd. China(Mainland)

1.The compound crusher can crush large materials, and the discharging granularity can be adjusted at will without the board hammer and lining plate abrasion.

2.It adopts the no-grizzly-bar structure to avoid blocking, which is suitable to crush materials with much moisture and silt content.

3.The elastic adjustment structure will help discharge materials that can’t be crushed, thus avoid damaging the equipment.

4.The long life bearing is arranged horizontally to crush high temperature materials like cement clinker. The rotor of the compound crusher has special structure which won’t be worn once crushed.

5.The screw rod or the hydraulic pressure opener is installed in the back cavity and it’s easy to change quick-wear part.

1.Big crushing ratio, grain-size can be adjusted arbitrarily.

2.Do not suffer the impact of plate hammer, lining board wearing.

3.No screen bar settings, crushing high water content, hydraulic large material clogging.

4.Using elastic and adjusting mechanism, not into broken material can self-control.

5.Won't cause equipment damage, bearing level decoration.

6.Long service life, low consumption ,stable running ,simple structure.

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 800 | 5-15 | 4p 30kw |

| 1000 | 10-30 | 4p 55kw |

| 1250 | 20-60 | 6p 90kw |

| 1500 | 30-80 | 8p 110kw |

| 1750 | 40-100 | 8p 160kw |

NOTE: You can also send a message to us by this email vip@zdzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!