Feeding Size: 65-300mm

Output Size: 3-60mm

Production Capacity: 12-1000t/h

Processing Materials: Granite, basalt, river pebbles, cobblestone, copper ore, iron ore, limestone, quartz stone, quartz, diabase, etc.

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Rock is formed in accordance with a certain way by natural mineral or glass aggregate with stable shape. Rock is a kind of solid mineral or the mixture of minerals. The rock under the sea is called reef, submerged reef or underwater sand. It is an integration with a certain structure composed of one or more minerals, a few of which include remains of creatures (fossil).

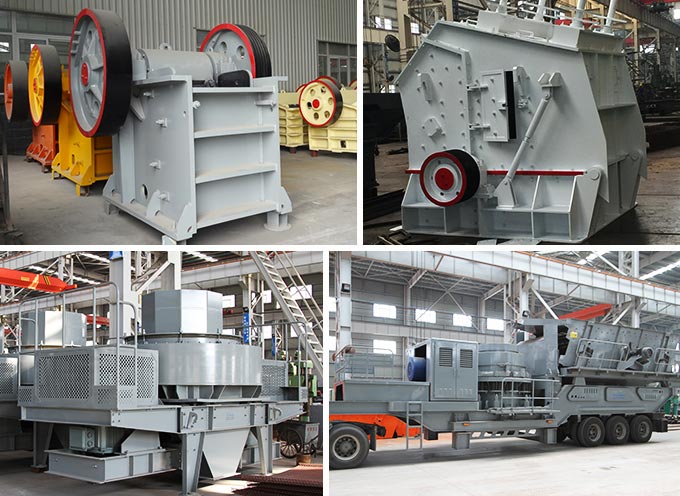

Rock crusher has unique structure, equipped with high-chromium plate hammer and unique impact liner. It is suitable for hard rock crushing, with high efficiency and energy saving. The output size is adjustable, the crushing process can be simplified, and it has advantages of high crushing ratio, high crushing efficiency, cubic product, selective crushing, etc. Rock crusher is widely used in hydropower, highway, artificial sand stone, crushing and other industries.

The rock crusher is mainly composed of crushing cone part, upper frame part, lower frame part, eccentric bushing and oil cylinder part, uniform feeding device, transmission part, lubrication and hydraulic part, etc. Transmission system often adopts belt drive. The cone gear has large contact ratio, low noise, high transmission power, so it adopts cone gear.

The hydraulic control system of rock crusher consists of three parts including structure, oil supply structure and automatically adjustable discharging port structure. The bracket structure is composed of a hydraulic cylinder and a piston. As the oil enters and leaves the hydraulic cylinder, the piston moves up and down, so that the bowl bearing is affected and makes the crushing wall move up and down to adjust the width of discharging port.

1. The rock crusher adopts the bottom hydraulic cylinder to control the movement of the mobile cone to achieve the function of adjusting discharge port. At the same time, it utilizes the energy accumulator in hydraulic system to protect the iron, which makes the adjusting ring, the support ring and the spring part of the original spring cone crusher omitted and greatly simplifies the structure of the equipment. So rock crusher has simple structure and reliable operation.

.jpg)

2. Compared with the same specification of crushers, the weight of the rock crusher is greatly reduced. In addition, from the whole structure, the spring cone crusher adopts cantilever structure, but the mobile cone spindle of rock crusher adopts simple strutbeam structure, which makes the main spindle of mobile cone has small eccentricity angle, so the crushing cone of the hydraulic crusher is relatively steep, and the crushing cavity long, greatly improving the uniformity of crushed minerals.

.jpg)

3. For spring cone crusher, it needs manual operation to adjust discharging port, and it takes a lot of time when the tread match is abnormal. When the iron is stuck, it often leads to halt production, and it is extremely difficult to process. And for rock crusher, it only needs to operate the hydraulic system control valve to complete the adjustment process. Under the same circumstances, it only needs to manipulate the hydraulic control valve to make the mobile cone move up and down, which greatly reduces the labor intensity and technical difficulty.

4. Rock crusher adopts sealed tube structure to prevent dust, which is more reliable than the water seal of spring cone crusher. For the water seal of spring cone crusher, in addition to water supply and drainage problems, there is the problem of mixing oil and water, which results in lubrication failure and other failures.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

NOTE: You can also send a message to us by this email vip@zdzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!