Processing Materials:coal sludge, slime

Daily running time:22h/d

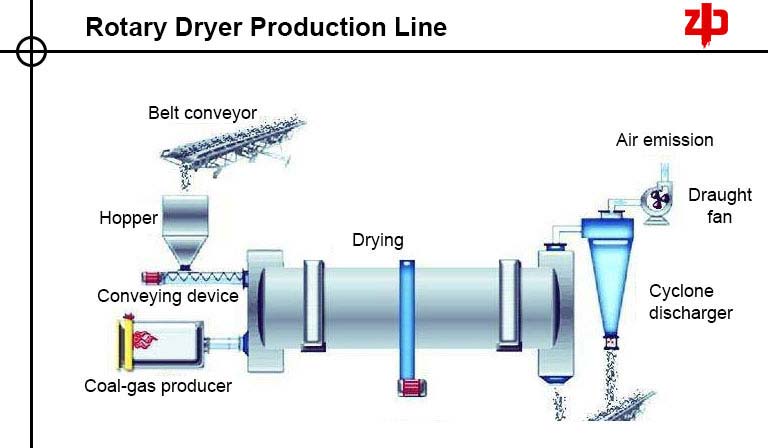

The related configuration:cone crusher、tertiary impact crusher、rotary dryer, vibrating feeder, ball mill ,etc.

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Customer cases:

1. The coal sludge drying production line is composed of various supporting equipment, not one of the equipment can complete the process.However, the coal sludge production line developed by the company can meet the use of many industries or materials, can adjust the equipment simply according to the actual needs of users. And the production of coal sludge is higher than that of matching equipment.

2. It has high degree of automation, high quality, low energy consumption. It reduces the emission of harmful substances, which is both green and reliable.

Coal slurry material:

1. Coal slurry refers to formed semi-solid with water, is a product of the coal production process, according to different varieties and different formation mechanism, the nature difference is very big, availability also has bigger difference, the species is numerous, widely used. Because of coal slurry with high moisture content, high viscosity, high water and low calorific value etc. many other adverse conditions, it is difficult to realize industrial using.

2. our company called dry experts for the coal industry market situation and the characteristics of coal slurry, around the technical research and practice again and again, carefully creating the coal slime drying equipment, to deal with coal slurry material, in order to improve the application scope and value of coal slurry.

Case process:

1. coal slurry crushing : firstly, crush the coal slime material by two crushing processes : jaw crusher and tertiary impact crusher. The size of the coal slime must meet the actual requirements, otherwise it will be not good to the next process.So this is very important.

2. coal slurry grinding: put the crushed coal mud into the ball mill to grind.

In order to make high finished product , the coal mud will carry out two grinding processes inside of ball mill, so that can improve the quality of raw materials, and then the next process will be carried out after the discharge.

3. Coal slime drying: in this stage, we usually adopt the dryer or slime coal drying, the working principle is same, let slurry into the cylinder body wall with consequent copy grinding plate, it grabbed the supplies and sprinkle continuously, make the material thermal contact area increases greatly, improve the drying rate and promote material to move forward.The finished product is made from the lower part of the other end.

4. Finished product packaging: the final material will be used as raw material after screening.

NOTE: You can also send a message to us by this email vip@zdzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!