Production capacity: 30-800t/h

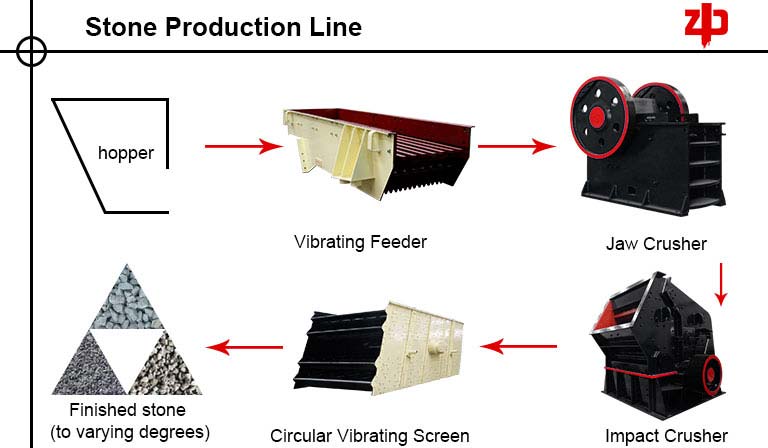

Component equipment: Jaw crusher、impact crusher、vibrating feeder、belt conveyor 、screening equipment ,etc.

Technical advantages:highly automatic, high compression ratio, high efficiency, large processing quantity, cubic shape of finished product with minimum needle and slice shaped product.

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Customer cases:

1. Stone crushing Plant is mainly composed of crushing equipment, vibrating feeder, screening equipment, belt conveyor, etc, the specific choice of types and specifications of the crushing equipment according to the production requirements of customers.

2. Our company supply the customer service is a stone crushing production line is mainly composed of jaw crusher and impact crusher, and other auxiliary equipment, the whole production line don't take up much land area, compact structure, materials can be efficient circulation between each working procedure, greatly improved the capacity of production line.

Production process:

1. Need for processing and broken stone used in vibrating feeder into the jaw crusher, maintain uniform feeding, not in order to improve the excessive feed processing, because of excessive feeding not only failed to increase production, also easy to cause breakdown of the equipment.After the rough-breaking process is completed, it will enter the impact crusher, which can be broken into second crushing, which can break up the materials using impact energy, no dead zone, and repair the grain shape of the stone.

2. After the broken stone processing ,need to use circular vibrating screen for screening, sieved stone can enter into the next procedure, cycle to complete crushing demand, qualified stone shipping to the finished products warehouse by belt conveyor.

The maintenance of production line:

1. Strictly observe the opening sequence of all the equipment, check the inside of the equipment before starting, the components are whether missing, fastener is whether fastening.

2. Regularly clean the bearing of the relevant equipment, replace the lubricating oil.

3. Use more liquid lubricating oil in winter to avoid impurities.

4. Make the maintenance record of the equipment, overhaul the number of parts to be changed in time.

5. In case of serious malfunction of a device, it should stop feeding and shut down, so as to avoid causing a bigger failure.

NOTE: You can also send a message to us by this email vip@zdzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!